From Rolled Rings to the finished slewing bearing

At our facility in Bautzen, Germany, we manufacture slewing bearings using state-of-the-art CNC technology and modern production methods. Every step of the process is carried out with precision and care – from the first chip to the finished bearing.

Our customers benefit not only from advanced technology, but also from the expertise of our highly qualified team. With many years of experience, our specialists ensure that every bearing meets the highest standards of reliability and performance.

Thanks to our optimized and efficient production processes, we are able to combine short delivery times with uncompromising quality. This means you receive a product that is manufactured with engineering excellence – durable, precise, and tailored to your application.

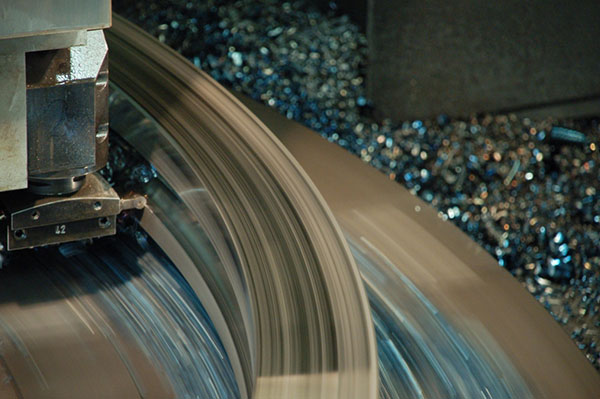

Turning

Turning of plane and circumferential surfaces as well as raceways on CNC vertical-lathes and universal lathes

Drilling

Drilling of through-holes and threaded holes on CNC drilling machines

Gear Cutting

Cutting of internal or external gearing using CNC gear-shaping and CNC gear-milling machines

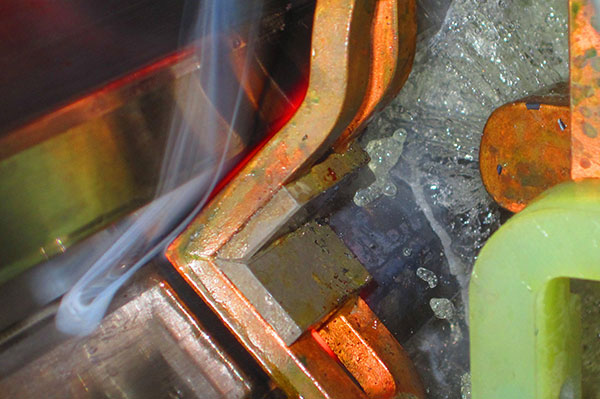

Hardening

Hardening of raceways and gear teeth on induction hardening systems

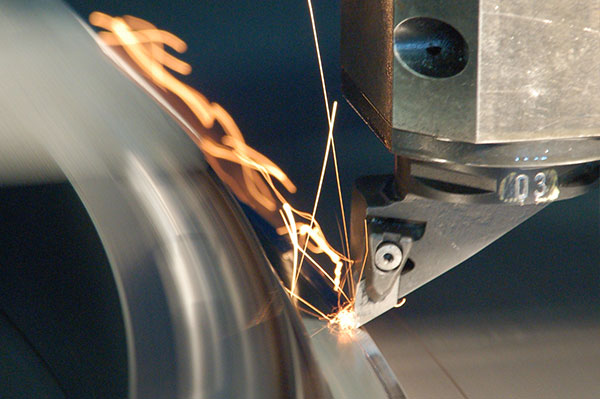

Precision Turning / Grinding

Precision turning or grinding of raceways, centerings, and other critical surfaces

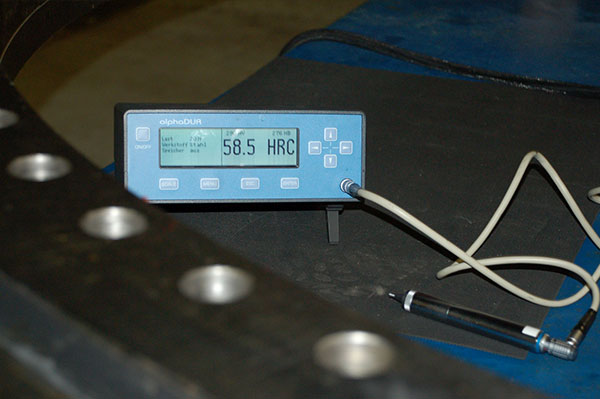

Inspection

Inspecting individual rings for dimensional accuracy as well as surface hardness and case depth of the raceways

Surface Protection

Applying surface treatments such as black oxide, passivation, flame-sprayed galvanizing, paint coatings, etc.

Assembly

Assembling the rings, rolling elements, spacers, seals, and any additional special components

Final Inspection

Performing final checks on the completed slewing bearing, recording bearing play or preload, torque values, radial and axial run-out